Glass Processing Machinery

Glass Processing MachineryStrategic partnerships like with Schiatti Angelo, SRL demonstrates DeGorter, Inc.'s focus on the highest quality glass processing products. Their reputation in the glass industry is second to none and why our partnership with them has lasted over 50 years.

DeGorter is the exclusive distributor for Schiatti Angelo in the United States, Canada and the Caribbean Islands. Download General Catalog

More versatile and economical than robotic arm solutions, The Turnover offers automatic processing of varying sizes in succession without any operator interference.

Drilling solutions capable of handling any glass drilling application with models that can be added in a line or as a stand-alone machine.

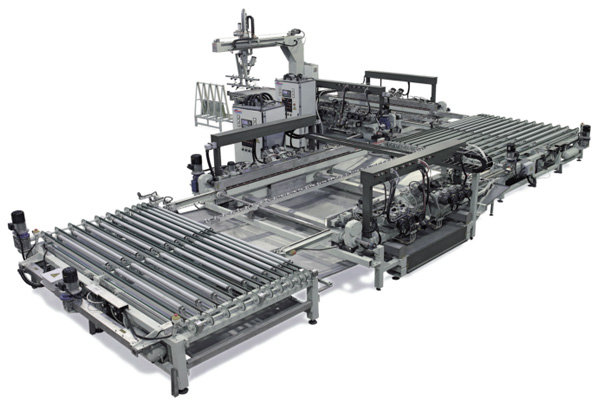

Ideal for uninterrupted large-scale production facilities with runs of constant glass size, a double edger grinds and polishes each side simultaneously, thereby insuring perfect squareness. Capable of a variety of profiles (pencil-BFT & flat-BFP), glass thicknesses and finishes.

Industrial lines of vertical edging equipment in pencil (AR/RI Series) and flat edges (FPS Series) that handles glass pieces as small as 2" x 2" and thicknesses from 1/8" to 2 1/8" or thicker upon request.

When you need a machine to do specialized work, these are the best at doing their specific jobs.